Advanced CFD Techniques for Fuel Systems

In the realm of fuel system simulations, Computational Fluid Dynamics (CFD) has emerged as an indispensable tool. This article delves into cutting-edge CFD techniques specifically applied to fuel system modeling, offering insights into how these advanced methods are revolutionizing the field of simulations for fuel systems.

The Evolution of CFD in Fuel System Modeling

Computational Fluid Dynamics has come a long way since its inception. In the context of fuel systems, it has evolved from simple 2D models to complex 3D simulations that can accurately predict fluid behavior in intricate geometries. Modern CFD techniques allow engineers to create computer models that closely mimic physical prototypes, saving time and resources in the development process.

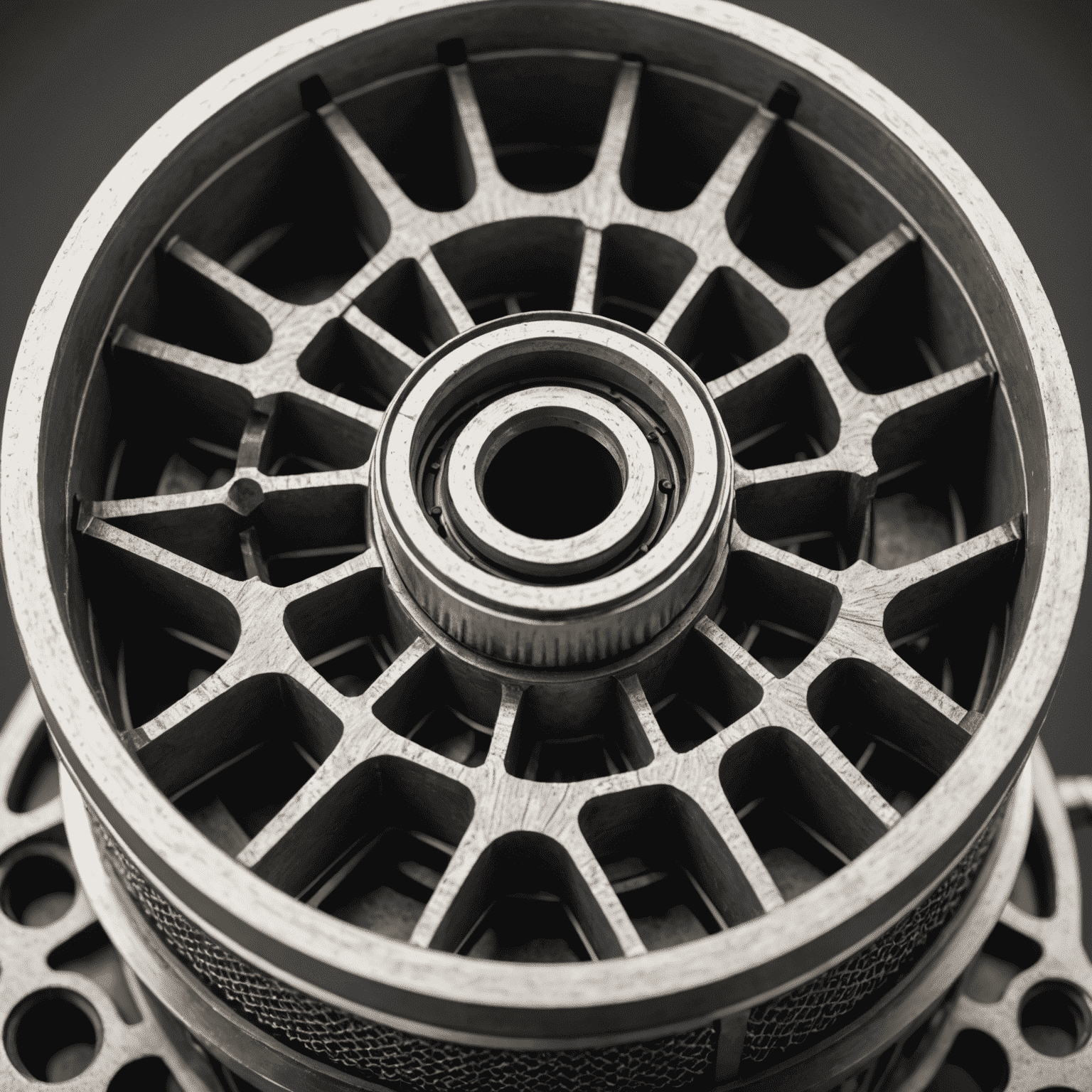

Advanced Meshing Techniques

One of the key advancements in CFD for fuel systems is the development of sophisticated meshing techniques. Adaptive mesh refinement and unstructured grids have significantly improved the accuracy of simulations, especially in areas with complex geometries such as fuel injectors and combustion chambers.

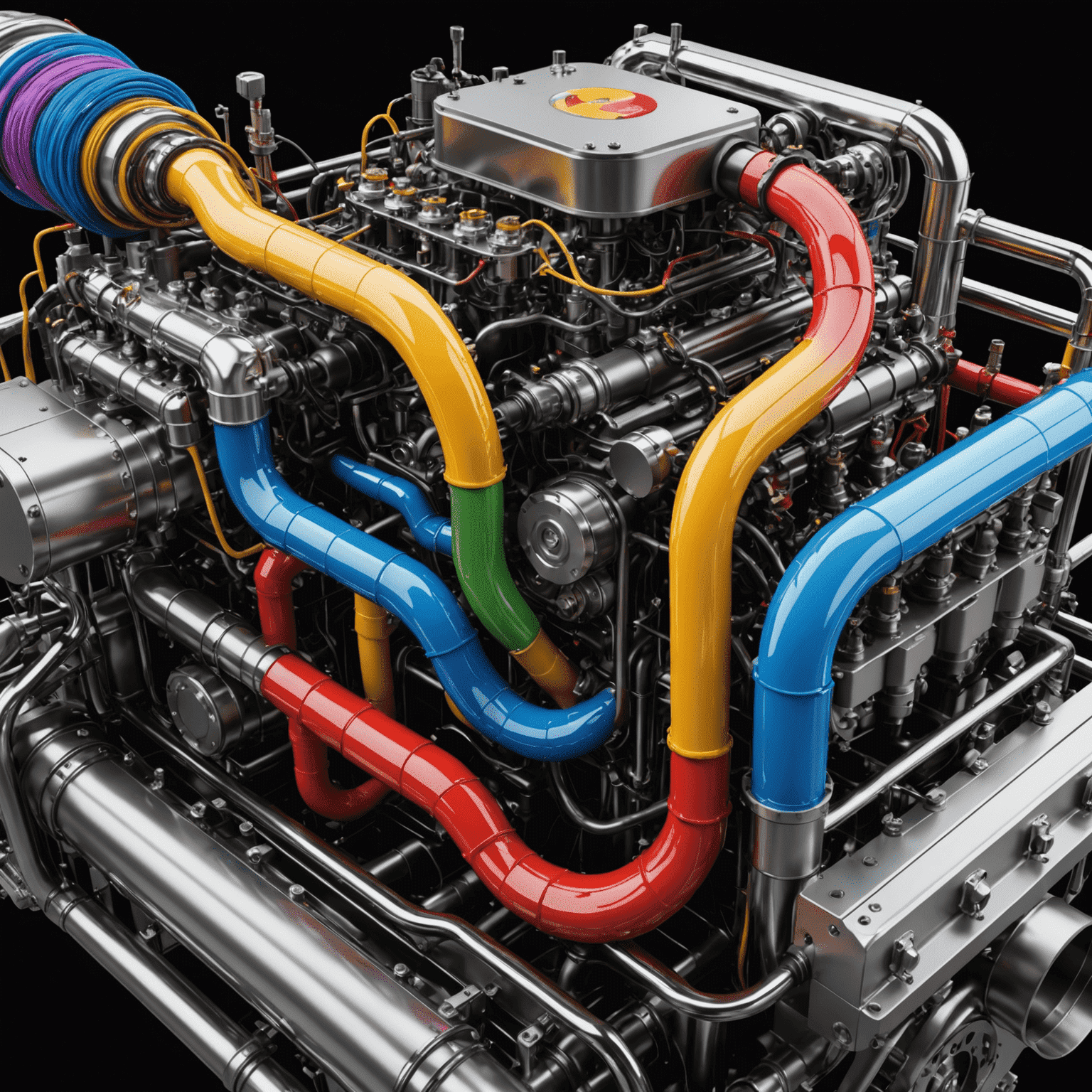

Multi-Phase Flow Modeling

Fuel systems often involve multi-phase flows, such as the interaction between liquid fuel and air. Advanced CFD techniques now incorporate sophisticated models for phase change, cavitation, and droplet formation. These models provide crucial insights into fuel atomization and mixing processes, which are essential for optimizing engine performance and reducing emissions.

Turbulence Modeling Enhancements

Accurate turbulence modeling is critical for fuel system simulations. Recent advancements in Large Eddy Simulation (LES) and Detached Eddy Simulation (DES) techniques have significantly improved our ability to capture complex turbulent flows in fuel systems. These methods provide a more detailed understanding of fuel-air mixing and combustion dynamics.

Integration with Artificial Intelligence

The integration of machine learning algorithms with CFD is opening new frontiers in fuel system modeling. AI-assisted CFD can help in optimizing simulation parameters, predicting outcomes, and even generating design alternatives. This synergy between AI and CFD is accelerating the development cycle of fuel systems.

Real-Time Simulation Capabilities

Advancements in computing power and CFD algorithms have made real-time simulations of fuel systems possible. This capability is particularly valuable for developing control systems and for training purposes, allowing engineers to interact with the simulation and observe immediate effects of parameter changes.

Conclusion

The field of CFD for fuel systems is rapidly evolving, with new techniques continually enhancing our ability to create accurate computer models of these complex systems. As we push the boundaries of what's possible in CFD, we're not just improving simulations – we're revolutionizing how fuel systems are designed, tested, and optimized. These advancements are crucial in our quest for more efficient, cleaner, and more reliable fuel systems across various industries.